2 Post pit

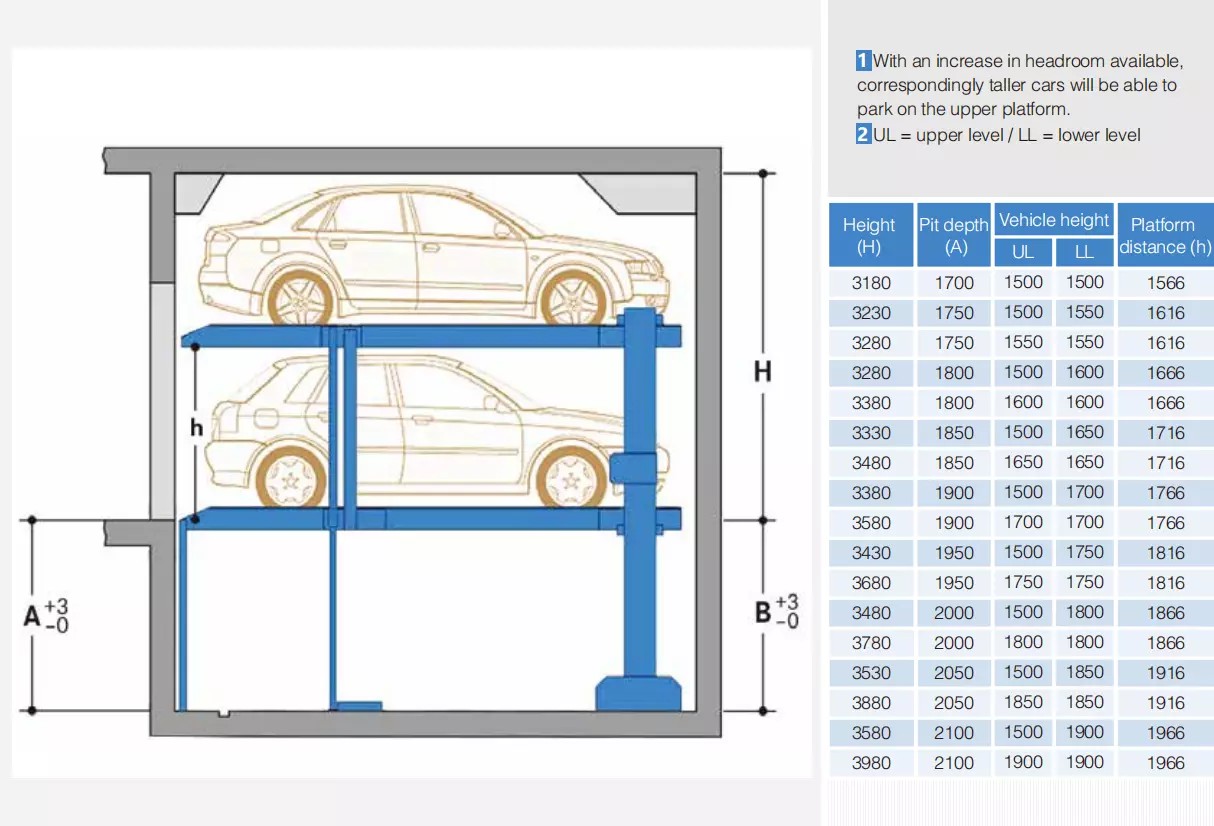

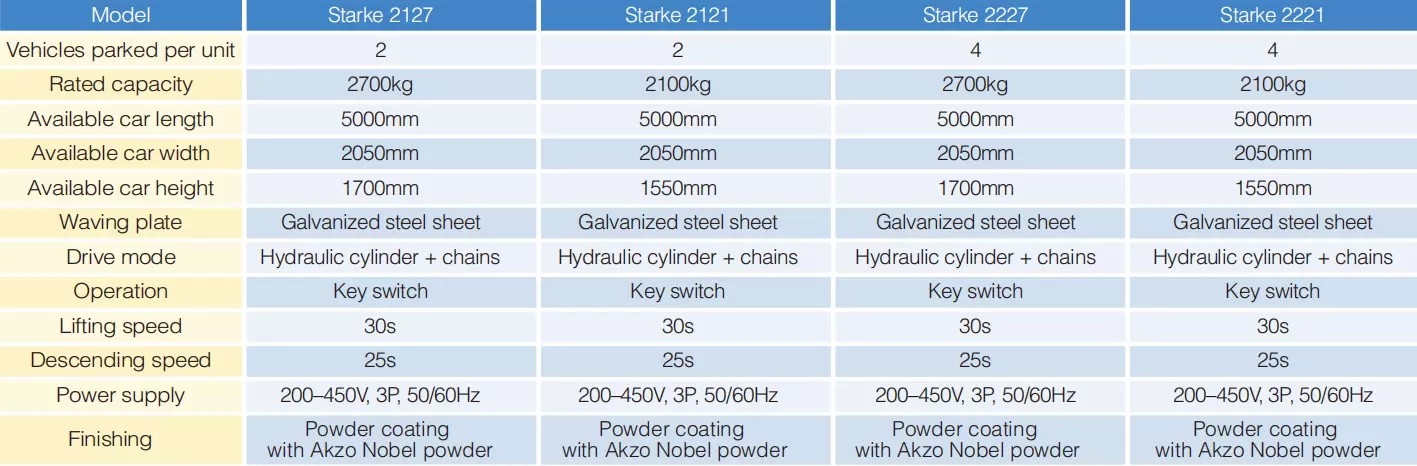

two post parking lifts, by platforms moving upwards from the pit or downwards to the pit, every vehicle can be parked or retrieved conveniently without moving any car else. Starke 2127/2121 is a kind of independent parking equipment, suitable for both commercial and residential parking purposes.

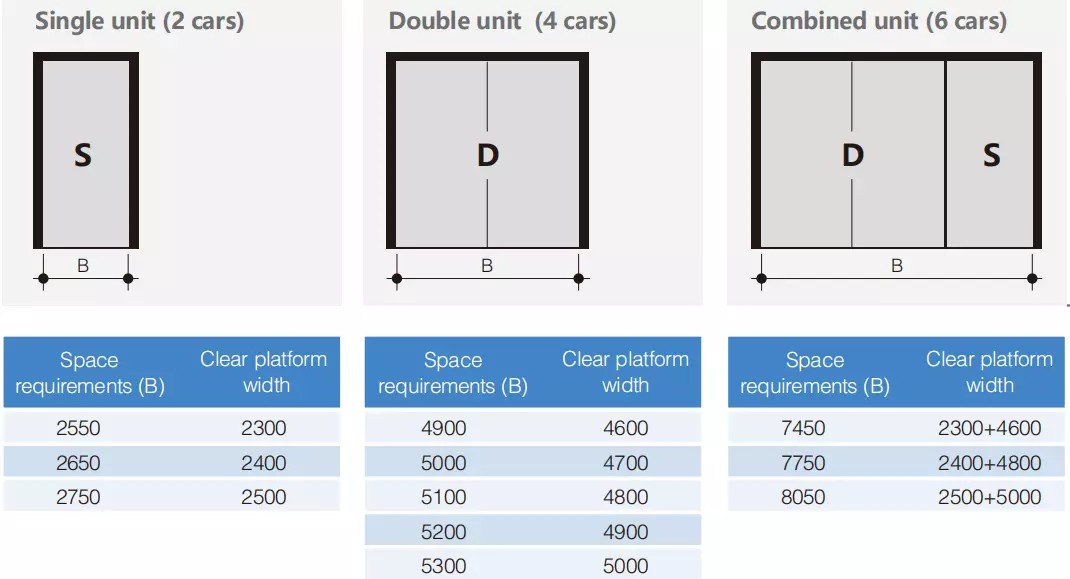

2 cars in a single unit (Starke 2127 and Starke 2121) and 4 cars in a double unit (Starke 2227 and Starke 2221) are both available

Parking space loads: 2100 kg and 2700 kg

Maximum 1700mm high vehicle can be parked in 1900mm deep pit, and 2300mm usable width is provided in only 2550mm overall width for a single unit, to make full use of the limited space. More available dimensions are optional for different project requirements.

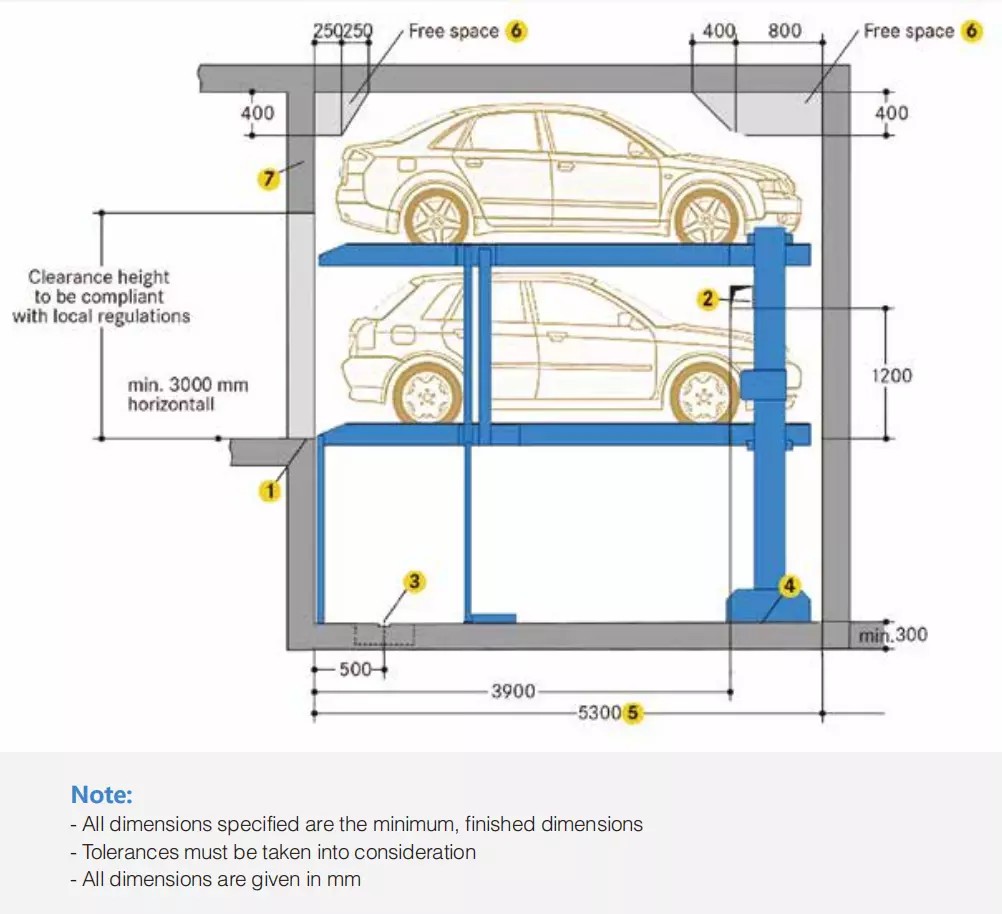

The structure should be placed in a pit with certain dimensions and reinforced by fixing posts to walls.

1 Post 2 Connection rod 3 Platform 4 Cylinder 5 Anti-falling lock 6 Oil hose

TUV compliant, which is the most authoritative certification in the world

Certification standard 2006/42/EC and EN14010

Low usage cost

When the platform moves down, it will be driven by gravity, so there is no electricity consumption for pump motor

New hydraulic system which owns Ashkenazi structure

he hydraulic system adopts German top-level product structure design, which is stable and reliable, avoid the maintenance troubles, and its lifetime is twice as long as that of the old one

Galvanized pallet

Far more beautiful and durable than observed, lifetime more than doubled. Anti-slip corrugated deck protect both vehicle and driver from possible slip and damage but still high-heel shoe friendly

Zero accident security system

All-new upgraded security system, really reaches zero accident

Dynamic locking device

Mechanical anti-falling locks in the front of platform as anti-falling device hold the platform in place

Multiple chain protection devices Chains loosen detection and break protection ensures the safety in case chain is loosen or broken

Unique guiding system

A full directions guiding system is adopted to make the movement stable all the way

More stable electric motors

Newly upgraded commercial power unit system with Siemens motor

Electrical auto control

Automatic shut-off if operator releases the key switch

Further strengthened main structure of the equipment

The thickness of the steel plates and the weld joints have been specially increased

Gentle metallic touch, excellent surface finishing

After applying AkzoNobel powder, color saturation, weather resistance and its adhesion are significantly enhanced

Rich color

Great care is taken with the treatment of lacquer face, in order to improve the quality of products on surface looking to the maximum extent

Strong adhesion

The weather resistance of the spray powder has better performance under special technology, which can stand wear and tear

Superior chains provided by Korean chain manufacturer

The life span is 20% longer than that of the domestic chains

Galvanized screw bolts based on the European standard

Longer lifetime, much higher corrosion resistance

Hydraulic centralized control

Perfect shared power pack unit solution

Laser cutting + robotic welding

Accurate laser cutting improves the accuracy of the parts, and automated robotic welding makes the weld joints more firm and beautiful

Mechanical anti-falling safety lock in the front of platform

Chains loosen detection and break protection

Full directions guiding system

24v electric lock release has no harm for operator

Electric protection for power over load or under voltage

Auto locking system in case electrical failure

Emergency stop button

Pressure relief valve and pressure compensate flow control valve

Limited switch at the top of the post. When the platform goes to the appointed height, it will automatic stopped to avoid the wrong operation

Overload protection device for hydraulic power pack

Synchronization shaft

1 Yellow-black safety marking:

- Compliant to ISO 3864, 100 mm wide, along the pit edges (see page 4 > Static calculations and construction works requirements <)

2 In case of intermediate walls:

- 150 x 150 mm opening for electric and hydraulic system cables and piping - After installation, do not close the opening

3 Recommended drainage channels:

- 100 x 20 mm, with a 500 x 500 x 200 mm drainage pit

- In case of installation of a sump pump, it is necessary to comply with the drainage pit dimensions specified by the pump manufacturer

4 Channels or undercuts / concrete haunches:

- Not allowed along the pit floor-to-wall joints

- Should channels or undercuts be necessary, the system width needs to be reduced or the pit needs to be wider

5 5000 mm vehicles length – 5300 mm pit length

6 Free spaces for any connections performed by the customer:

-Please ask Mutrade for the dimensions sheets

7 Lintel

Platform widths:

2300 mm (single units), 4600 mm (double units):

- For 2050 mm vehicle width (without outside mirror)

2400 – 2500 mm (single units), 4700 – 5000 mm (double units):

- For vehicles wider than 2050 mm (without outside mirror) - For units with intermediate walls - For units at the end of the driving aisle

For comfortable parking, entry and exit conditions platform widths upon 2300 mm are recommended. Reduced platform width means reduced parking comfort depending on the vehicle width, vehicle type, individual driving style, access situation of the garage.

The driving aisle width

The driving aisle width must comply with local regulations It is possible to combine different widths

Fixing of the system frames to the floor slab:

- Using base plates (approx. 15300 mm²) - Using adhesive anchor bolts M20 with 250 mm length - Hole depth is more than 250 mm - Concrete thickness of at least 300 mm

Walls:

- Front drive-in wall and rear wall in concrete - Perfectly flat wall surfaces - Without protruding sections such as border edgings, pipes and tubes, etc.

Concrete quality grade:

- Compliant of the static requirements of the construction - Min. C30 grade (for dowel fastening)

Frame bearing points:

- The specified lengths are expressed as mean value

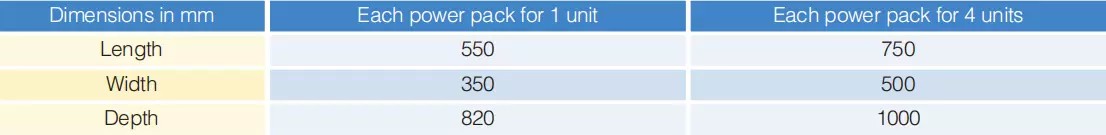

Hydraulic power pack placement options:

Located behind the parking lift Where this is not possible, it is necessary to arrange for an extra space above drive-in level (i.e. for a wall recess or a niche)

Cabling preparation to be performed by the customer:

- Up to the main switch to be in place prior to starting the installation operations - Connection to the main switch during installation - System functional check testing can be performed by the electrician provided by the customer

Grounding and potential equalization:

- To be performed by the customer compliant to local regulations

Connections required every 10 meters

Note:

For garages with doors the door manufacturer must be consulted before the electrical feed cabling is laid.

Scope of application

Suitable for residential buildings, office buildings and business premises, hotels Only for long-term users that have been instructed on how to use the system. For frequently changing users(e.g. for office, hotel and business premises or similar): - Only parking on top platform - Performance of technical system adjustments in necessary - Consultation with Mutrade is mandatory

Noise protection

- Insulation figure of the construction of min. Rw = 57 dB - Walls which are bordering the parking systems must be done as single wall and deflection resistant with min. m = 300 kg/ m² - Solid ceiling above the parking systems with min. m = 400 kg/ m² At differing constructional conditions additional sound absorbing measures are to be provided by the customer The best results are reached by separated sole plates from the construction. Increased noise protection: If increased noise protection must be provided planning has to be confirmed on a project basis by Mutrade.

Temperature

- System operating range: -10 to +40C (with unloading platforms lowering speed is reduced if less than +5C) - Humidity: 50% at +40C - In the event of changes to system conditions please consult with Mutrade

Drainage

Water leaks into the pit: - In the winter, up to 40 liters of snow water can possibly come with the wheel housings in just one parking process Recommended drainage channels: - Along the front end sections of the pit - Connecting to a floor drain or drainage pit (500 x 500 x 200 mm) - With manual emptying out of the drainage pit - Alternatively installation of a pump ordrainage channel into the sewerage system, to be performed by the customer Environmental safety: - Coating of the pit flooring is recommended - Installation of an oil and / or petrol separator unit between the drainage connection and the main sewerage system is recommended

Railings

Railings mandatory: - When exceeding the permissible, country-specific construction gaps and opening Safety fences mandatory: - When walkways resp. traffic passageways running alongside or behind Parklifts and / or systems positioned along border walls - Safety fences according to ISO 13857 to be performed by the customer (also during the construction phase)

Maintenance

- Mutrade and all the Mutrade partners abroad provide an installation and customer service network - Regular, annual maintenance is provided subject to the stipulation of a maintenance agreement

Protection against corrosion

- All operations listed in the Mutrade Cleaning and Maintenance Instructions are to be performed regularly (independently of maintenance operation) - Zinc-plated parts, components and platforms are to be kept clean of dirt, road-salt and any other debris (due to corrosion hazards) - Always keep the garage well ventilated and deaerated

Surface protection

- Please consider the information on surface protection!

Lighting

- Sufficient lighting of the driving aisle and of the parking places must be performed by the customer

Fire safety

All the safety requirements and all mandatory equipment (fire extinguisher and fire alarm system, etc.) must be performed by the customer

Construction alternations and /or modifications

- The right to construction or model modifications and/or variations is hereby reserved - The right to any subsequent part modification and/or variation and amendments in procedures and standards due to technical and engineering progress or due to environmental regulation changes is also hereby reserved